FACTORY

Automation and digitization are at the heart of Concox manufacturing. The

combination of the two has streamlined the entire production process, increased our

capacity, and lowered human errors,further improving our product quality and our

delivery efficiency.

SMARTER / FASTER / BETTER

Play Video

Smart Manufacturing

Play >

SMT Error

Avoidance System

Manufacturing

Execution System

Unattended

Warehouse

SMARTER / FASTER / BETTER

Play Video

Smart Manufacturing

Play >

SMT Error

Avoidance System

Manufacturing

Execution System

Unattended

Warehouse

SMT ERROR AVOIDANCE SYSTEM

Prevent errors in feeding.

Assist operators to control production.

System Structure

System Overview

SMT Advantage

SMT Error Avoidance System

System Structure

System Overview

Previous

Next

SMT Advantage

SMT Error Avoidance System

System Structure

System Overview

SMT Advantage

SMT Error Avoidance System

System Structure

System Overview

Previous

Next

SMT Advantage

SMT Error Avoidance System

MANUFACTURING EXECUTION SYSTEM

Enhanced Productivity With MES

System Structure

System Overview

MES Advantage

System Structure

System Overview

Previous

Next

MES Advantage

System Structure

System Overview

MES Advantage

System Structure

System Overview

Previous

Next

MES Advantage

UNATTENDED WAREHOUSE

System Structure

System Overview

UW Features

Advantage

System Structure

System Overview

Previous

Next

UW Features

Advantage

System Structure

System Overview

UW Features

Advantage

System Structure

System Overview

Previous

Next

UW Features

Advantage

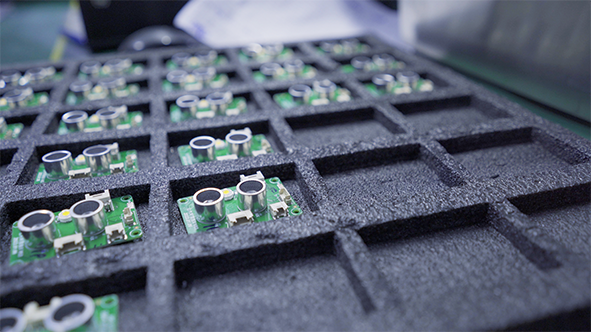

ASSEMBLY & PACKAGING

2

Manufacturing Bases

69,000㎡

Manufacturing Space

9

SMT Lines

600+

Factory Workers

10

Assembly Lines

6,000,000+

Annual Shipments

From Manufacturing to Support

9 SMT Lines / 10 Assembly Lines

Unmanned Warehousing System (UW)

1 Million Units Monthly Capacity

Quality Control

Production

ISO + QCC check sheets + SOP manual

Every step of production is precisely controlled to eliminate any

imperfections and inconsistencies caused by human interference.

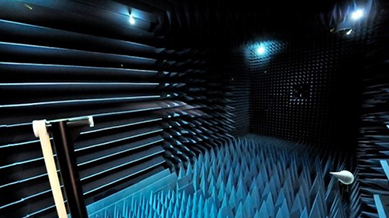

Reliability Test

Strict corporate standards

Jimi has spent nearly 10 million CNY implementing more than 50

stringent reliability and quality standards that exceed industry standards.

Millions has been investing to equip the R&D center in Huizhou with

a reliability test lab and a multi-probe OTA testing chamber, which will be completed 2023.

Millions has been investing to equip the R&D center in Huizhou with

a reliability test lab and a multi-probe OTA testing chamber, which will be completed 2023.

Contact Us

Please fill out the form below and click the "Submit" button. We will contact you once receive your inquiries.

SOLUTIONS & INDUSTRY

EN

EN ES

ES PT

PT TH

TH VN

VN JP

JP